INTRODUCTION Who do companies care about supply chain management? We know that food is always at the grocery store, and clothing at the department store. How they get there and who is making those items are there every single day? This is the job of supply chain manager.

In supply chain management we start with purchasing, some people call it Procurement. The second part is Manufacturing and Operation, where the product is made, and we have to do that quickly and being able to do on a day.to-day basis. The third stage is Logistic and Transportation. In order to deliver to customers. Summarizing, supply chain is about: Buy things, Make things and Move things.

Of course, modern supply chain extends beyond purchasing, operations, and logistics, and involves IT, designer, accountant, and collaborate with finance to create a budget that will maximize the return on investment.

PROFIT = REVENUE - COST Supply chain is about cutting cost, but cricually it cut costs that will hurt the company. In fact, modern supply chain must be dual contributors to profit: creating great products that arrive on time, and controlling costs by eliminating waste.

In order to create great products we need to know what customers want, and we also need to understand how to differentiate ourselves to our competitors. Considering two companies we have to ask the questions depicted on the figure below.

When the supply chain understand its goals, in the area of cost, quality, speed, flexibility, the supply chain is better able to make the customer happy and thus contribute to revenue. Moreover, by understanding what is not required can eliminate waste, and so, better control costs.

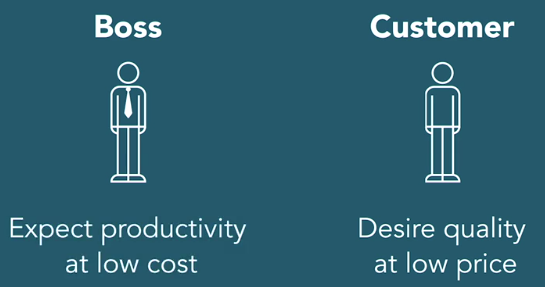

In supply chain we have two bosses: the boss that expect productivity and low cost, and the second boss which is the customer that desire quality at low price.

DEVELOPING GOOD BUYER AND SUPPLIER Supply chain manager has the responsibility to find a great supplier. If a company put their brand in the hand of poor supplier, they risk to lose customers. It is important, before to choose a supplier, to ask if this supplier help the company to be better. Another thing to consider is the Production Capability of the supplier, for example, can the supplier produces milion of batteries on time, abd at best quality? Moreover, can we trust on the supplier about our new secret phone? Are the supplier committed to improve its battery?

In modern supply chain is important to understand the relationship between buyer and supplier. Just in great relationship, buyers and suppliers share needs. One partner need great parts at certain time, and the other partner need directions and reasonable timeline to complete the order. It is common to use Scorecards to communicate expectations, perceptions, and to start a discussion about future needs. This help both buyers and suppliers to work together to innovate. consider also that buyers and suppliers are not exclusive, and that make the company feel more stable. Moreover, this can motivate those suppliers through competition. That make each of those suppliers better. It also expose the buyer to the different options for improving their end products.

THE BULLWHIP EFFECT It happen when stores try and predict customer buying patterns, but they are rarely right. In order to protect the company against running out stock, and store more inventory than needed. This is in fact the pain point: Uncertainty. Uncertainty of demand, requires more inventory, and that is expensive to buy and hold. The distributors try and guess orders of consumers. The primary supplier also wonders how much the distributor will be ordering. These are three level of uncertainty. This is called Bullwhip Effect. The key to avoid the Bullwhip Effect is the communication of customer sales data and changing desires, strategic partnership between the company and their suppliers. To keep the Bullwhip Effect in check consist also to have retail share sales data with the distributors. Another key point is to develop good relationship with the partners and customers.

Another important aspect is to use the Push Strategy, where a product is created and pushed to the customer, using promotion and marketing before they even know they want it. And then, when they realize they need it, they will be waiting for them at the store. Push Strategy ensures immediate inventory and lower price. As ppose, we can use the Pull Strategy, where interest for a product drives demand for creating the product. Here the company wait for the customer to make a specific order. Pull Strategy ensures product customization and better design/quality. Postponement is a combination of both Push and Pull Strategy, where a set of raw materials is customized at a finishing warehouse in response to a customer’s order. For example, the company to the same wood chair, but let the customer choose the color. The company put an uncolor chair in the showroom and allow customer to choose paint.

From a statistical point of view, could be really useful to apply Time Series and Forecasting to this sort of data in order to prevent the the Bullwhip Effect. This statistical approach is also called Demand Forecasting which is a field of Predictive Analytics that analyze current and historical facts to make predictions about future unknown events.